Polymers are ubiquitous in everyday life and have multiple applications including medical, transport, electrical, construction, coatings, packaging as well as in many consumer products. Increasing public interest in environmental issues, global warming, diminishing fossil fuel resources, and rising production costs are driving the growth of sustainable and green chemistry alternatives to traditional industrial processes. The next generation of industrial plastics and resins will incorporate biomaterials derived from renewable resources and be designed for cost-effective recycling or biodegradation. Natural components diverted from waste streams in biomass processing are of particular interest, as they bring reduced dependency on petrochemicals.

Over the past decade, considerable progress has been made to replace petroleum-based polymers with sustainable materials from renewable biomass feedstock, especially for polyester and polycarbonates derived from Bisphenol-A (BPA), an endocrine-disrupter chemical. Canada, along with the EU, as well as several US states are targeting a complete ban of this chemical. There are numerous commercial polymers wherein BPA is currently utilized, such as inks, toner, can liners, coatings, fiberglass/casts, water bottles, and a variety of consumer products. However, the cost impact of most sustainable (renewable) derived materials, render them largely prohibitive for replacing the current commercial petroleum-based polymer applications, especially BPA based resins.

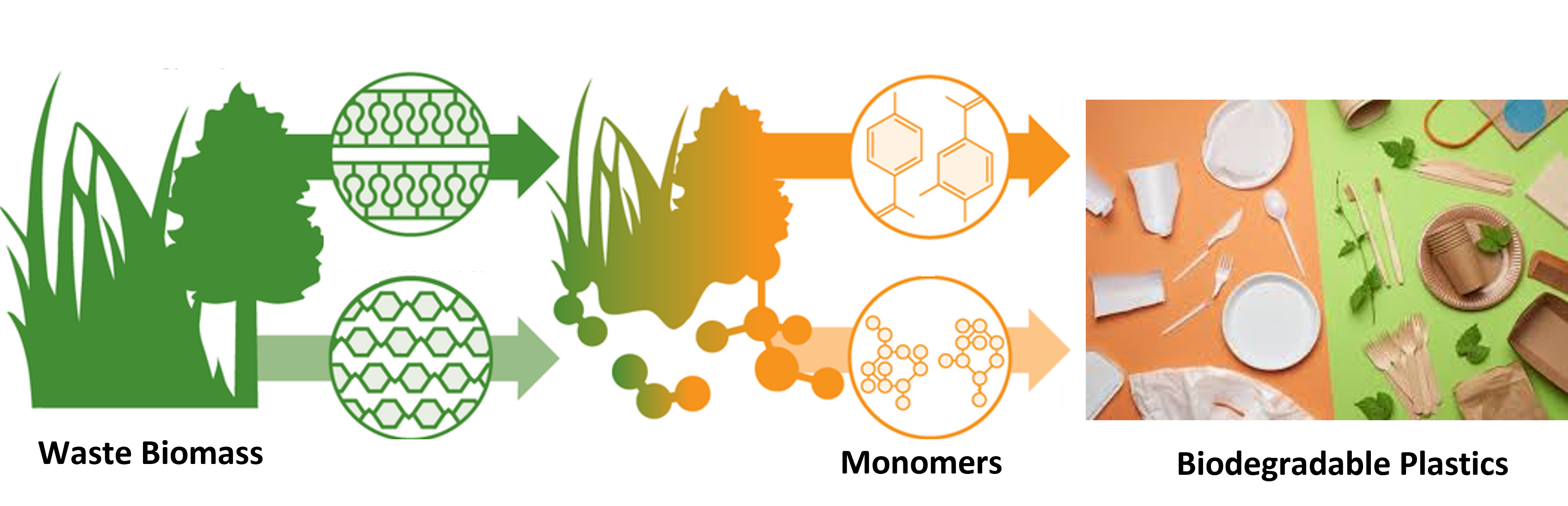

The most prevalent commercial bio-based polymers are polyurethanes and polyesters, obtained from bio-based monomers such as propane-diol, butane-diol, succinic acid, lactic acid, and dimer acids (& diols) derived from corn, sugar or plant-based oils. However, these sources are food-based, and critics have suggested more sustainable monomers from non-food biomass.

The present research program proposal focusses mainly on the use of two Canadian biomass resources that are abundant, inexpensive and are non-food based. Both are derived from forestry byproducts, such as from Rosin acids and/or Lignin byproducts obtained from the Kraft Pulp Process. Transforming these biomass feedstocks into economical and suitable building blocks for the synthesis of a wide variety of polymers to replace current petroleum-based polymers is the central challenge of our research program. To obtain polymer properties not inherent to the aforementioned biomass derivatives, we intend to also explore the incorporation of recycled building blocks obtained from the de-polymerization of plastic waste bottles made from polyethylene terephthalate. The use of this feedstock will also lessen the environmental disposal burden, and its incorporation with other bio-based materials will allow for the tailoring of specific and critical polymer properties. The primary focus of this research program is to target BPA based polymer replacement with a more sustainable building block derived from Rosin acids and Lignin biomass.

Our goal, is to explore non-Bisphenol A polymer products, which are not cost prohibitive for applications4 in the construction industry, coatings, packaging, automotive parts, medical devices, DVDs, safety equipment, LCD screens, water bottles, and in emerging fields such as materials for 3D printing and energy storage. Many of the properties associated with these products include high performance, hydrophobicity, clarity, hydrolytic stability, oxygen impermeability, and above all, low cost and which will be addressed in our research program.